For decades, industrial sectors have contended with a fundamental operational bottleneck, where the rigid coupling of control software to specific hardware has stifled innovation and saddled companies with exorbitant costs and risks associated with modernization. This long-standing dependency on proprietary, closed systems has created a challenging environment for plants navigating the transition to Industry 4.0, where agility, interoperability, and data continuity are paramount. Facing the threat of hardware obsolescence and the daunting prospect of “rip-and-replace” overhauls, many facilities have been forced to delay critical upgrades, thereby hindering their ability to adopt next-generation technologies. The introduction of a truly open, software-defined Distributed Control System (DCS) marks a significant turning point, addressing these deeply rooted inefficiencies that, according to industry reports, have cost industrial enterprises a substantial portion of their annual revenue. This evolution represents not just an incremental improvement but a foundational change in how industrial processes are managed, controlled, and optimized for the future.

A Paradigm Shift in Industrial Operations

Decoupling Software from Hardware

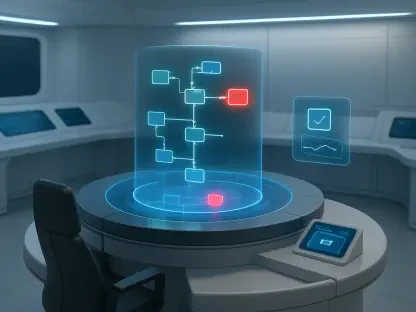

The core innovation driving this transformation is the fundamental decoupling of control software from the physical hardware on which it operates, a concept brought to life by the EcoStruxure Foxboro Software Defined Automation (SDA). This architectural departure breaks the decades-old model of vendor lock-in, where operational logic was inextricably tied to a specific manufacturer’s proprietary equipment. By virtualizing the control layer, the Foxboro SDA enables industrial facilities to deploy and run control applications on any suitable computing hardware, effectively creating a more open and flexible ecosystem. This separation is the key enabler for a lower-risk, phased modernization strategy, allowing plants to upgrade their systems incrementally without requiring a complete and disruptive shutdown. Companies can now protect their substantial existing investments in instrumentation and infrastructure while progressively integrating new capabilities. This approach directly mitigates the immense financial and operational risks associated with traditional rip-and-replace projects, which often lead to extended downtime and budget overruns, thereby making technological advancement more accessible and manageable.

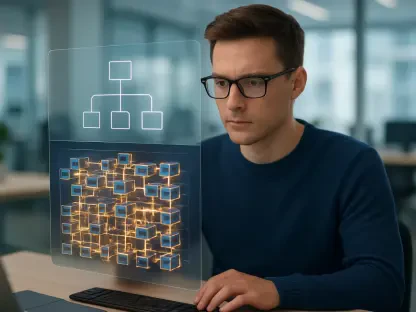

Enhancing Operational Agility and Scalability

By abstracting the control logic from the physical layer, software-defined automation introduces a level of operational agility previously unattainable in traditional DCS environments. Plant engineers and operators can now develop, test, and deploy control strategies far more rapidly, using modern software development practices within the industrial context. This agility allows for quicker adaptation to changing market demands, new production requirements, or evolving regulatory landscapes. Furthermore, the system architecture is inherently scalable, enabling facilities to expand their operations or integrate new process units without being constrained by the physical limitations or proprietary nature of existing hardware. Powered by the EcoStruxure Automation Expert (EAE), the Foxboro SDA offers a validated, high-availability solution that streamlines workflows from design and engineering to operation and maintenance. This streamlined process ensures digital continuity across the entire plant lifecycle, keeping data connected and consistent to improve both process efficiency and product quality while laying a robust foundation for future growth and innovation.

Building a Future-Ready and Secure Foundation

Fortifying Cybersecurity for IT and OT Convergence

As industrial operations become increasingly connected, the convergence of Information Technology (IT) and Operational Technology (OT) has elevated cybersecurity from a secondary concern to a mission-critical priority. Recognizing this imperative, the Foxboro SDA is engineered with a secure-by-design philosophy, adhering to the stringent IEC 62443-3-3 cybersecurity standard for industrial automation and control systems. This proactive approach embeds robust security measures at every level of the system architecture, from the hardware-agnostic platform to the application layer. It provides a fortified defense against the growing threat of cyberattacks that target critical infrastructure, ensuring the integrity and availability of plant operations. By building on an internationally recognized security standard, the system simplifies compliance for operators and provides a trusted framework for managing the unique security challenges posed by the interconnected IT/OT landscape. This focus on security is crucial for building the trust required to fully leverage the benefits of digitalization in an increasingly hostile digital environment.

A Platform Engineered for Next-Generation Technologies

The Foxboro SDA has been engineered not merely as a solution for today’s challenges but as a future-ready platform poised to integrate seamlessly with the next wave of industrial technologies. Its open, software-defined nature creates the ideal environment for deploying advanced applications driven by Artificial Intelligence (AI), machine learning, and edge computing. These technologies can be layered onto the control system to unlock new levels of efficiency, from predictive maintenance that minimizes unplanned downtime to autonomous operations that optimize complex processes in real time. This forward-looking architecture ensures that industrial enterprises can continuously evolve their capabilities without being locked into a static system. The consensus among industry analysts is that this move represents a major milestone, providing the essential digital backbone required for facilities to fully embrace the principles of Industry 4.0. This new model of industrial automation was designed to move beyond incremental improvements, offering a transformative path toward a more intelligent, autonomous, and resilient industrial future.