The electrical trade in Australia is undergoing a seismic shift as robo-assisted tools become integral to the industry, particularly for Level 1 electricians tasked with constructing and maintaining vital electricity distribution networks. These professionals, once defined by their hands-on labor in challenging and often hazardous conditions, are now navigating a landscape where automation and robotics are reshaping their daily responsibilities. From reducing physical risks to accelerating project timelines, this technological wave is not just a trend but a fundamental evolution of the trade. It challenges electricians to adapt to new tools and systems while offering opportunities to enhance their roles in a rapidly modernizing energy sector. As Australia pushes toward a more sustainable and complex grid, the integration of these advanced technologies signals a turning point, urging a deeper look into how they impact operations, safety, and skill requirements for those on the front lines of electrical work.

Transforming Daily Operations

Boosting Efficiency with Advanced Tools

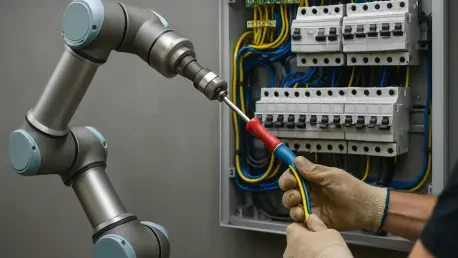

Robo-assisted technologies are dramatically enhancing the efficiency of daily tasks for Australian electricians, marking a departure from the labor-intensive methods of the past. Tools like sensor-equipped drones can perform overhead line inspections in mere hours, a process that once took days of manual effort, while robotic cable pullers manage underground installations with unmatched precision. This shift allows projects to be completed faster, meeting tight deadlines that are increasingly common in the industry. Beyond speed, these tools minimize human error by providing consistent performance, ensuring that tasks like cable tensioning are executed with exacting standards. For Level 1 electricians, this means a transition from performing every step manually to overseeing automated processes, enabling them to tackle larger-scale projects with fewer resources. The impact is clear: work that once demanded extensive physical exertion now benefits from technological precision, redefining productivity in the field.

The safety benefits tied to these tools are equally transformative, addressing long-standing risks inherent in electrical work. By delegating high-risk activities such as pole climbing or heavy lifting to robotic systems, electricians are spared exposure to dangers like falls or strain injuries. Automated lifting systems, for instance, handle the burden of heavy equipment, while drones assess hazardous areas without putting human lives at risk. This reduction in physical danger allows professionals to focus on strategic oversight rather than perilous manual tasks. Moreover, the data collected by these tools—such as real-time feedback from smart torque devices—enables better decision-making, preventing issues before they escalate. As a result, job sites are becoming safer environments, and electricians are empowered to prioritize planning and quality control over sheer physical effort, fundamentally altering the nature of their day-to-day operations.

Streamlining Workflow Through Automation

Automation through robo-assisted tools is also streamlining workflows for electricians, creating a more cohesive and responsive approach to project management. Systems like automated diagnostic tools can instantly identify faults in electrical lines, providing data that guides repair efforts with pinpoint accuracy. This eliminates the guesswork that often delayed past projects, allowing teams to allocate resources more effectively. Additionally, integration with digital platforms means that electricians can monitor progress remotely, coordinating with robotic systems to ensure tasks are completed in sequence. This level of connectivity reduces downtime and enhances communication across job sites, particularly in remote or sprawling areas common in Australia. The result is a workflow that operates with greater fluidity, where technology bridges the gap between planning and execution.

Beyond immediate tasks, these tools contribute to long-term operational improvements by generating actionable insights through data logging. For instance, drones equipped with thermal imaging not only detect current issues but also track patterns over time, helping to predict maintenance needs before failures occur. This predictive capability shifts the focus from reactive fixes to proactive strategies, a significant advantage in an industry where uptime is critical. Electricians are thus positioned as data interpreters, using insights from robotic systems to inform decisions that enhance reliability. This evolution in workflow management underscores how automation is not merely a tool but a catalyst for rethinking how electrical projects are approached, ensuring that every step, from inspection to installation, is optimized for efficiency and foresight.

Adapting to a Modern Energy Grid

Navigating Complexity with Digital Integration

As Australia’s energy grid grows more intricate with the rise of distributed energy resources like solar and wind, robo-assisted tools are proving essential in managing this complexity. Automated inspection drones and remote-controlled ground robots are now deployed to monitor grid components, ensuring stability in a system that must balance diverse inputs. Level 1 electricians are increasingly required to interact with technologies such as SCADA for real-time oversight and IoT sensors for detailed data collection, necessitating a grasp of digital communication protocols. This integration enables the grid to remain responsive to fluctuations, a critical factor as renewable energy adoption accelerates. However, it also places new demands on electricians to understand and maintain these systems, blending their traditional expertise with a layer of technological proficiency that was once outside their scope.

The shift toward digital integration also means that electricians must adapt to a grid that operates as a connected network rather than isolated segments. Robo-assisted systems facilitate this by providing continuous feedback on load balance and fault detection, allowing for immediate adjustments that prevent outages. This level of automation ensures that issues in one part of the grid don’t cascade into broader failures, a growing concern with decentralized energy sources. For electricians, the challenge lies in interpreting this data to make informed decisions, often in real time, while ensuring compatibility between robotic tools and existing infrastructure. This role as system integrators highlights a profound change in their responsibilities, where managing automation becomes as critical as physical repairs, positioning them at the forefront of a smarter, more resilient energy landscape.

Enhancing Grid Reliability Through Technology

Robo-assisted tools are not only aiding in managing grid complexity but also significantly enhancing reliability, a priority for Australia’s sprawling energy networks. Technologies such as robotic process automation software monitor network dynamics, identifying stress points that could lead to failures long before they occur. This proactive approach, supported by drones that detect vegetation encroachment or line degradation, ensures that maintenance is timely and targeted. Electricians, in turn, must oversee these systems, ensuring that data translates into actionable repairs or upgrades. The result is a grid that operates with greater uptime, meeting the demands of both urban centers and remote regions where reliability is often a challenge due to harsh environmental conditions.

Furthermore, the adoption of these technologies fosters a level of precision in grid management that was previously unattainable. Smart sensors embedded in robotic tools log detailed metrics on everything from voltage levels to equipment wear, providing a comprehensive view of grid health. This allows electricians to prioritize interventions based on data-driven insights rather than relying solely on periodic inspections. Such precision reduces unnecessary disruptions and extends the lifespan of critical infrastructure, a vital consideration as energy demands grow. By leveraging these tools, electricians contribute to a grid that not only meets current needs but is also prepared for future expansion, ensuring that Australia’s energy systems remain robust in the face of evolving challenges.

Addressing Safety and Compliance Challenges

Mitigating New Risks in a Robotic Era

While robo-assisted tools have reduced traditional hazards in electrical work, they introduce a new set of risks that Level 1 electricians must address to ensure safety. Unexpected robotic movements, sensor malfunctions, or software glitches can pose dangers on job sites, requiring strict protocols for machine safeguarding and pre-use testing. Additionally, the connectivity of these systems opens the door to cybersecurity threats, where a breach could compromise critical infrastructure. Electricians are now tasked with understanding these vulnerabilities and implementing protective measures, a responsibility that extends beyond physical safety to digital integrity. Adhering to evolving Australian standards, such as AS/NZS 3000:2018, becomes paramount in this context, ensuring that both human and machine interactions are secure and compliant with regulatory expectations.

The complexity of managing these risks necessitates a comprehensive approach to safety training tailored to robotic systems. Electricians must learn to anticipate potential failures, whether mechanical or digital, and respond effectively to prevent accidents. This includes routine checks on robotic tools to confirm functionality and secure data transmission protocols to guard against unauthorized access. The focus on cybersecurity, in particular, marks a significant shift, as the consequences of a breach could disrupt entire energy networks. By integrating these safety practices into daily routines, electricians help create job environments where technology enhances rather than endangers operations. This dual emphasis on traditional and emerging safety concerns underscores the evolving nature of their role, where vigilance in both physical and virtual realms is essential.

Establishing Robust Compliance Frameworks

Compliance with safety standards in the era of robo-assisted tools requires electricians to navigate a landscape of updated regulations and best practices. Beyond adhering to established codes, there is a need to stay informed about new guidelines specific to automation and connected systems, which are continually being developed to address emerging risks. This involves regular updates to training programs to cover the latest protocols for robotic tool operation and data security. Electricians must ensure that every piece of equipment meets compliance standards before deployment, a process that adds a layer of administrative responsibility to their technical duties. This rigorous approach to compliance not only protects workers but also safeguards the public by maintaining the integrity of electrical systems.

Moreover, establishing robust compliance frameworks means fostering a culture of accountability on job sites, where every team member is aware of the standards governing robo-assisted tools. This includes documenting usage and maintenance logs for robotic systems to track performance and identify potential issues early. Such meticulous record-keeping supports audits and inspections, ensuring that operations align with national safety expectations. For electricians, this shift toward documentation and oversight represents a departure from purely hands-on work, emphasizing the importance of procedural diligence. By embedding compliance into every aspect of their workflow, they contribute to an industry that prioritizes safety and reliability, even as it embraces cutting-edge technology to transform traditional practices.

Preparing for the Future of the Trade

Upskilling for a Hybrid Workforce

The future of electrical work in Australia hinges on the ability of Level 1 electricians to upskill and adapt to a hybrid workforce where human expertise and robotic assistance coexist. Training programs are evolving to include modules on robotics, basic AI applications, and digital twin simulations, equipping professionals with the tools to manage automated systems effectively. This educational shift is crucial for maintaining relevance in an industry where tasks once done by hand are now executed by machines. Electricians must learn to program and troubleshoot these systems, blending their deep-rooted knowledge of electrical principles with newfound digital literacy. The emphasis on continuous learning ensures that they can handle both the physical and technological demands of modern projects, positioning them as indispensable contributors to the energy sector.

This push for upskilling also reflects a broader recognition that technology is an enhancer, not a replacement, for human skill in the trade. By mastering robo-assisted tools, electricians can focus on complex problem-solving and strategic planning rather than repetitive manual labor. Training initiatives are designed to foster adaptability, encouraging professionals to view technological advancements as opportunities to expand their capabilities. Partnerships between industry bodies and educational institutions are facilitating access to cutting-edge resources, ensuring that learning remains practical and relevant. As a result, electricians are being prepared not just for current challenges but for future innovations, creating a workforce that is versatile and forward-thinking in its approach to an ever-changing field.

Embracing Lifelong Learning and Innovation

Beyond initial upskilling, the commitment to lifelong learning is becoming a cornerstone for electricians aiming to thrive amidst technological advancements. Continuous professional development programs are increasingly vital, offering updates on the latest robotic tools and safety protocols to keep pace with rapid industry changes. This ongoing education helps professionals stay ahead of emerging trends, such as the integration of AI-driven diagnostics into grid management. Electricians who embrace this mindset are better equipped to innovate within their roles, proposing solutions that leverage both their practical experience and technological insights. This culture of learning fosters resilience, ensuring that the trade remains dynamic and responsive to Australia’s evolving energy needs over the coming years.

Innovation, supported by lifelong learning, also encourages electricians to contribute to the development of new tools and systems tailored to local challenges. For instance, collaborating with tech developers to refine robotic inspection tools for Australia’s unique environmental conditions can enhance their effectiveness. This proactive engagement with innovation ensures that the tools electricians use are not only cutting-edge but also practical for real-world applications. By viewing education as a career-long journey, professionals in the field can drive progress, shaping the future of electrical work to be safer, more efficient, and aligned with national priorities. This dedication to growth and creativity ultimately strengthens the industry, building on past efforts to integrate technology as a foundation for future success.